Get a quick contact: +86-18853787347

Our Product

It involves heating of metal to the plastic state and then applies the pressure with hand hammer or power hammer to obtain predetermined shape of the product. The term forging is also used to define the plastic deformation of metals at forging temperature into required shape using compressive forces that are exerted through dies by means of a hammer, a press, or an upsetting machine.

Strict quality control

Customize your product shapeaccording to your needs

Good service guarantees thequality of your products

Full-line production system, fasterproduction speed

About Forging———

INTRODUCTION

The forging is a metal forming process.

Forging is an intricate manufacturing process that entails shaping the metal using a series of localized compressive forces. These forces are delivered blow by blow utilizing a hammer or even a die. Forging is sometimes referred to as impression die forging, closed die drop forging, or Near-Net.

Reliability High Pressure Point

Key Components

NEED A QUOTE AND MORE INFORMATION IMMEDIATELY?

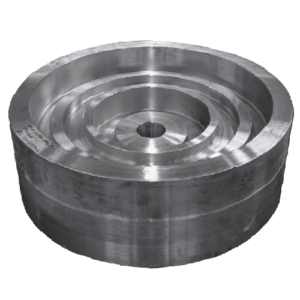

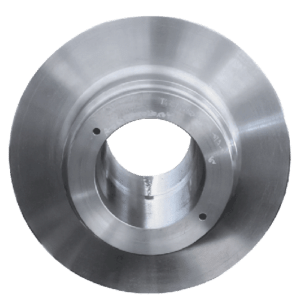

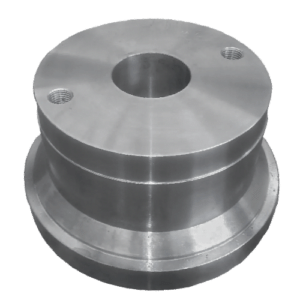

Our Products———

INTRODUCTION

01.

Refined grain structure.

02.

Better strength of parts.

03.

Reasonable degree of accuracy.

04.

Forgings could be easy welded.

05.

Achievement of smooth surface finish.

06.

No or negligible machining required.

07.

Saving of material as wastage is less.

08.

Faster production rate.

09.

Best suited for mass production.

10.

Reduced dead weight of forged parts.