Get a quick contact: +86-18853787347

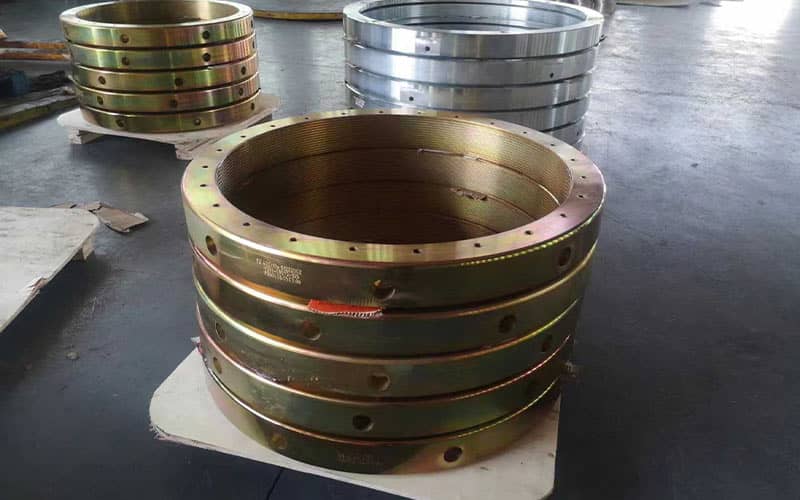

Flanges

Forged steel products for flanges are typically used in applications where a secure, leak-proof connection is needed between pipes, valves, or other components.

Forged steel products for flanges are typically used in applications where a secure, leak-proof connection is needed between pipes, valves, or other components. These products are made by heating a piece of steel to a high temperature, then shaping it using a hammer or press.

Some common forged steel products for flanges include:

Weld neck flanges:

These are the most common type of flange and are used in high-pressure and high-temperature applications. They have a long, tapered hub that is welded to a pipe, and the flange end provides a surface for bolting the flange to another component.

Slip-on flanges:

These are used in low-pressure applications and are slipped over the end of a pipe and then welded in place.

Blind flanges:

These are used to seal the end of a pipe or vessel and are bolted in place.

Threaded flanges:

These are used in low-pressure, non-critical applications and have threads that allow them to be screwed onto a pipe.

Detailed introduction

01. Material

Carbon steel, alloy steel, stainless steel, nickel-base alloy steel

02. Heat Treatment

Normalizing, thermal refining, tempering, annealing, solution annealing, precipitation strengthening

03. Testing

Destructive and non-destructive test

04. Processing

5-axis machining center, precision CNC vertical & horizontal lathe, CNC drilling machine

05. Grade

C45/1045, 42CrMo4/4140, 34CrNiMo6, 30CrNiMo8, 4340, 4130, 18CrNiMo7-6