Get a quick contact: +86-18853787347

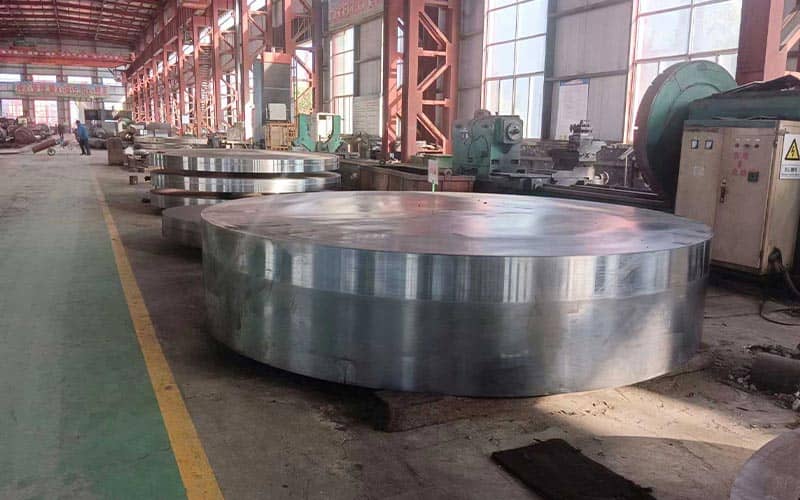

Discs

Disc forgings, also called forged discs or plate forgings, are a component made by forging (thickening or lengthening) the heated materials on the forging equipment.

Disc forgings, also called forged discs or plate forgings, are a component made by forging (thickening or lengthening) the heated materials on the forging equipment. Through thickening, the height of the materials is reduced and the diameter is increased. The internal fiber line is transferred from being horizontal with the axis to being radial with it. The metal grains are also refined and improved in this process. Therefore, compared to discs cut from plates or rods, forged discs have greater hardness, toughness, impact strength and fatigue resistance.

Detailed introduction

01. Material

Carbon steel, alloy steel, stainless steel, nickel-base alloy steel

02. Diameter Range

≤1.5m

03. Thickness

≤500MM

04. Heat Treatment

Normalizing, thermal refining, tempering, annealing, solution annealing, precipitation strengthening

05. Testing

Destructive and non-destructive test

06. Processing

5-axis machining center, precision CNC vertical & horizontal lathe, CNC drilling machine

07. Grade

C45/1045, 42CrMo4/4140, 34CrNiMo6, 30CrNiMo8, 4340, 4130, 18CrNiMo7-6